Noi

"In this land, tough yet enchanting, we've chosen to value every single resource it bestows upon us. With an eye on the future, we strive in the present, constantly refining ourselves in anticipation of upcoming challenges. We've embarked on the path of quality production, a commitment that brings satisfaction to both us and our clients. We no longer see it merely as a challenge, but as a deeply shared objective."

Pier Francesco Petroni

Administrator and Production Manager

Lucrezia Marzovillo

Administration and Sales Office

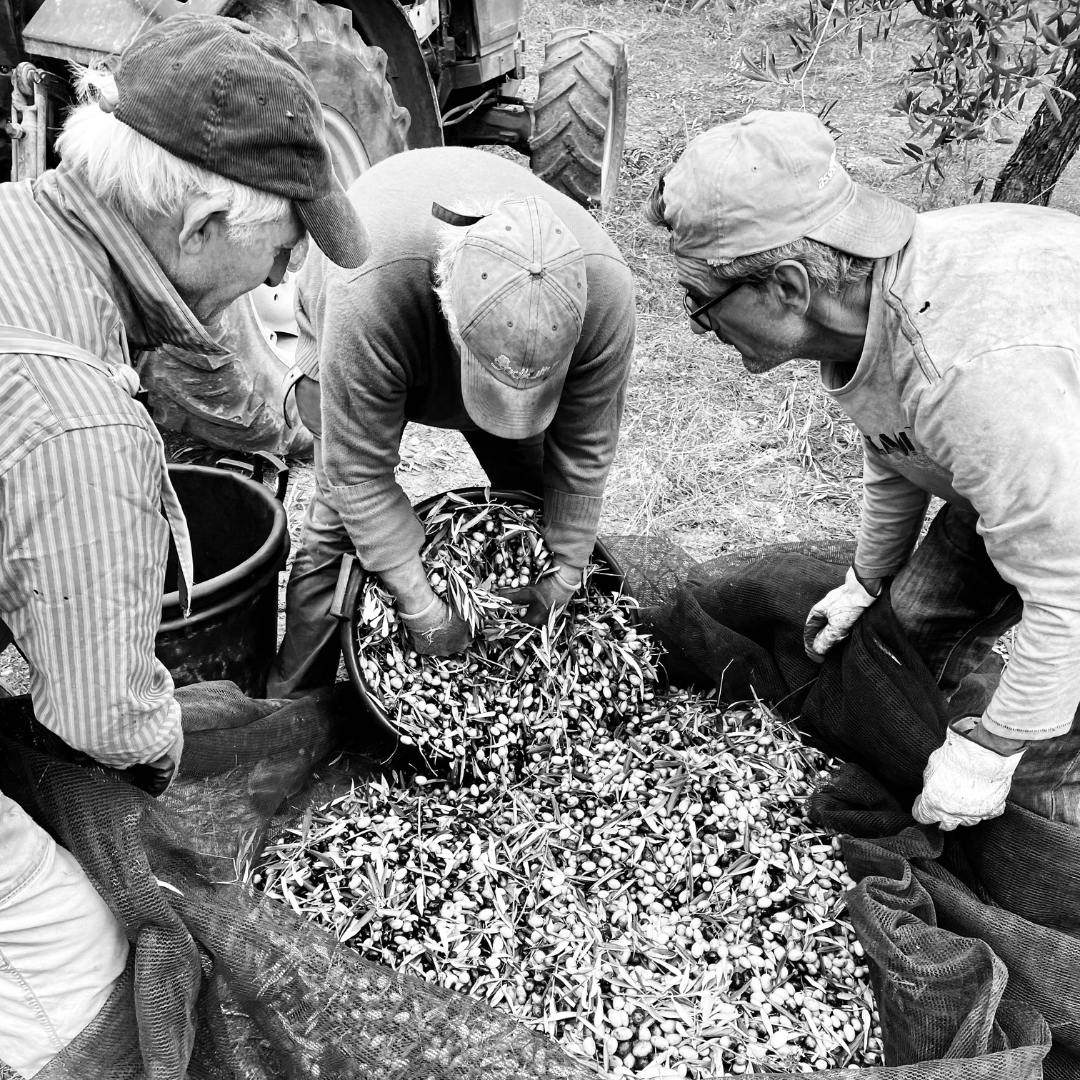

Sabino, Enzo e Mimmo

The team inside the fields

Green Gold

This liquid gold, extracted using both traditional and innovative methods and exclusively from our farm's olives, is a true delight for the palate. Rich in flavor and health benefits, it epitomizes the goodness and authenticity of Pugliese food. And not just the oil, but all local products are the result of an agriculture that respects both the environment and traditions, prioritizing quality and authenticity.